Data - the New Gold

What is data and why is it the new gold?

Ramesh Gulati tells us that data is a piece of information; in a raw or unorganized form; used as the basis for reasoning, discussion, calculations, further processing, and communication (Reference #1). It can be quantitative, qualitative, structured, unstructured, semi-structured, analog, digital, etc.

Why is data such a hot topic?

In the maintenance, reliability, operations, and Artificial Intelligence (MROA) world, data plays a significant role. Because of its importance, leaders need to understand why a large portion of businesses today are dissatisfied with their data quality. This is especially true as the value and importance of data continues to increase as technology advances.

Data is the key component to decision making. Most companies do not lack data. In 2019, there were over 8 billion connected devices. By 2025 that number exceeded 25 billion and 50 billion is the estimate by 2030. Each device potentially creates multiple data points on a second/minute/hourly/daily/weekly/monthly/etc. basis. The total volume of data generated was estimated at 180 zettabytes (ZB) in 2025. A ZB is equal to one trillion gigabytes (Reference #2). Reliabilityweb.com conducted a survey in 2024 and found that less than 60 percent of respondents trusted their data (Reference #3). Most companies are lacking the quality data necessary to make informed decisions. The saying is “garbage in/garbage out.” Therein lies the problem.

Why is poor data quality a problem?

In addition to poor decision-making opportunities other effects of poor data include:

- Production losses

- Delayed or incorrect maintenance actions

- Inefficient use of labor and materials

- Weak reporting

- Audit risk

- Safety incident/injuries

- Environmental impact

- Equipment breakdowns

- Negative financial impacts

- Regulatory violations

How does a company improve data quality?

First, there needs to be a data plan. Second, they need a governance process in place to ensure the data plan is followed and continuously updated. Figure #1 shows there is a great amount of detail, planning, work, and execution required to deliver a plan resulting in clean, reliable data (Reference #4). Once the data plan is in place it needs to continuously progress while remaining flexible as technology changes. Governance is the foundation piece of data science. It establishes the rules behind how data is obtained and handled. Governance is the discipline to achieve the business outcomes desired from data capture.

Figure #1 shows that there are many pieces to the data puzzle and many decisions involved. There is no one size that fits all. For a data plan to work, each company will need to account for financial considerations, workforce maturity, skillsets (current and future), desired outcomes, strategic plans, and more. There is no silver bullet that will immediately transform data quality from “garbage” to “gold.”

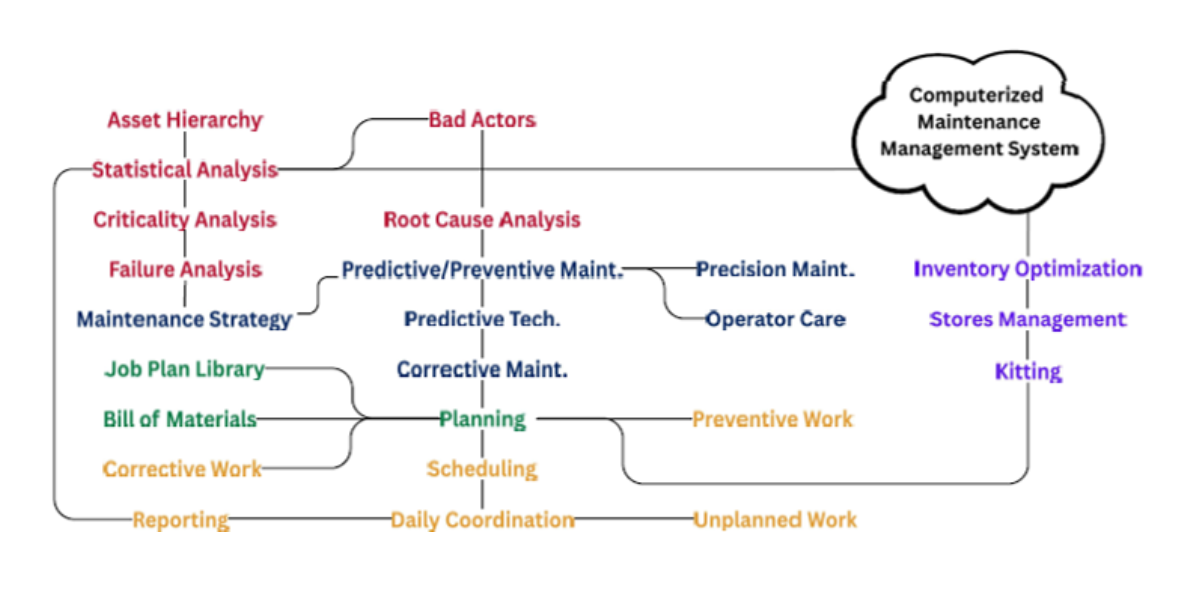

Figure #2 is an example of information that is entered into a Computerized Maintenance Management System (CMMS) for an organization (Reference #5). The items listed in Figure #2 are all tasks/data points determined to be important by MROA groups. In most cases, in addition to these data points, subitems under each one also require data capture. Much of the information will be used to gauge performance of the various departments based on key performance indicators (KPIs) and reporting. Additionally, there is a desire in many companies to incorporate AI into the data process. When combined, all of these factors create an environment where data needs to be as accurate as possible, and the information in the CMMS will need to be “cleaned up.”

Why does the CMMS data need to be cleaned up to use Artificial Intelligence (AI)?

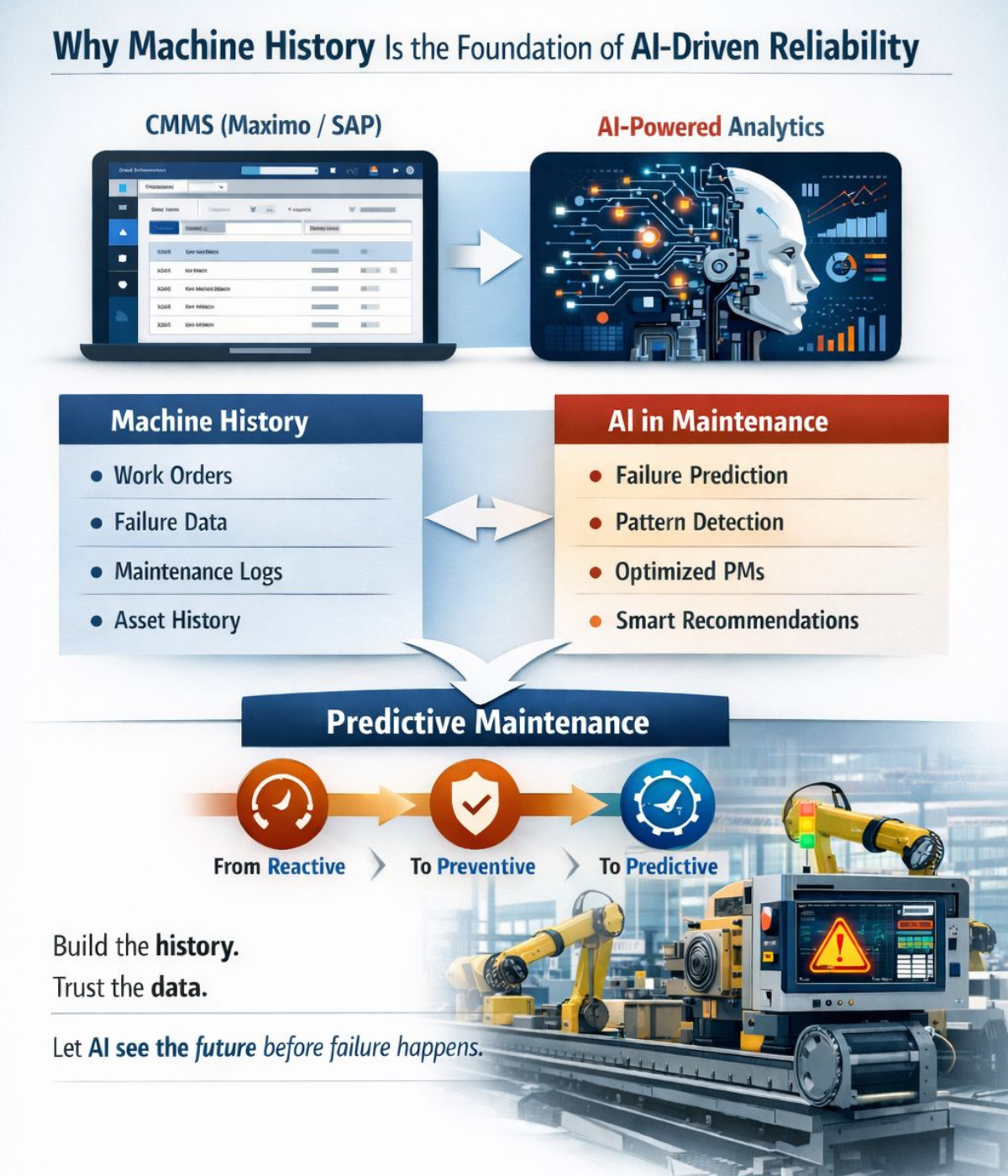

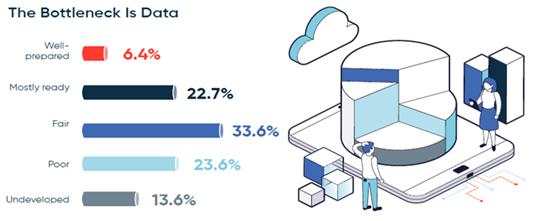

Figure #3 shows the connection between the CMMS, AI, maintenance results, and improvement (Reference #6). There is a misconception in organizations that a CMMS full of information/data means they have good data. Volume does not mean quality. AI models learn from patterns and if those patterns are in chaos, AI will give you garbage predictions. Examples of CMMS data issues that are commonly found in CMMS systems include free-text fields with no standards, asset hierarchies missing or inconsistent, failure codes unused or misapplied, bad timestamps, and incomplete records. AI cannot fix what is not properly documented (Reference #7). Figure #4 shows that less than 30 percent of respondents to UpKeeps

2026 State of Maintenance

survey believe their data is ready to use AI. These results further emphasize the urgency to improve data quality (Reference #8).

Only after a company has created a data plan, governance, usable data, and an AI vision, can they move forward. The strategy is not “go deploy AI,” but to make a workflow AI-ready, prove value, and scale up. Examples of the potential early AI wins when implementing a good adoption program may include:

- Work request triage

- Work order structuring

- Suggested troubleshooting

- Schedule optimization

- Parts forecasting

- Documentation prompts

A detailed graphic on page 26 of UpKeep's State of Maintenance 2026 Report gives more information on what each application does and why it works.

Are there further steps once data is clean?

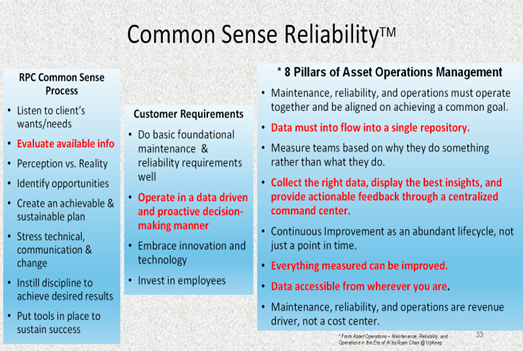

After achieving quality data and AI adoption there will still be needed improvements. The digital transformation journey will have taken a significant step forward, but like most other aspects of the MROA process this will be a continuous improvement reality. The perfect plan does not exist, but companies should continue to strive to ascertain and achieve the plan that works best for their organization. At Russ Parrish Consulting (RPC) we practice Common Sense Reliability. Figure #5 shows our RPC Framework. The items in red correlate with data actions. Data is a key concept to any successful reliability program. Have questions on how your organization will benefit from a strong data plan, please reach out, we would welcome the opportunity to guide the process.

References

- Ramesh Gulati (2015), Certified Reliability Leader Pocket Dictionary, pg.29

- Google AI Search 2-17-26

- © Copyright 2024, Reliabilityweb.com. All rights reserved. Reliabilityweb.com®, Uptime®, and A Reliability Framework and Asset Management SystemTM are the trademarks or registered trademarks of Reliabilityweb.com and its affiliates in the USA and in several other countries.

- Graphic from @orcaorgit on LinkedIn

- Graphic provided by Bill Leahy from Unturning Steel, The MADE IN AMERICA Community

- Graphic from Akshdeep Singh Rakhra on LinkedIn

- Maven Asset Management information from presentation material

- UpKeeps 2026 State of Maintenance survey