The Business Approach to Maintenance

Telling Leadership What They Want To Hear

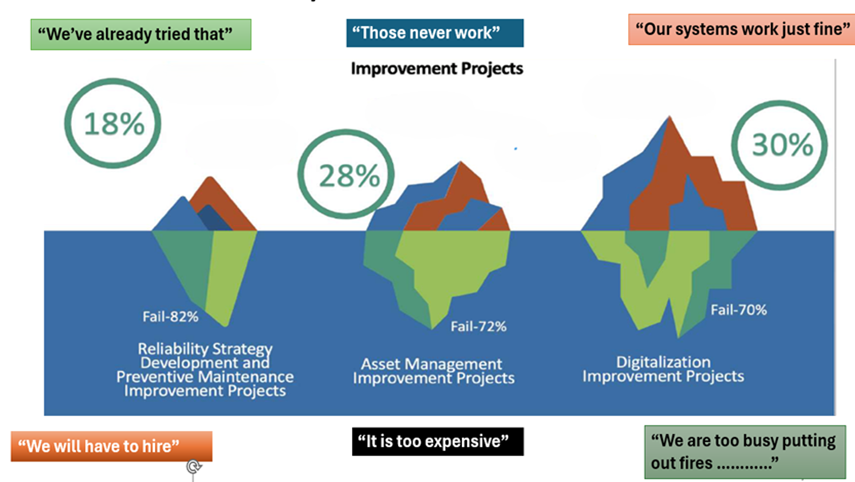

Why is it so hard to get a company to take on maintenance and reliability initiatives and why are the initiatives usually not “successful” (Fig #1)? This is a common occurrence/problem in the maintenance, reliability, and operations (MRO) arena. Is there a way to increase the chances of success? The answer is yes, with several factors impacting both success and failure.

Fig#1 – Success or Failure

© Copyright 2024, Reliabilityweb.com. All rights reserved. Reliabilityweb.com®, Uptime®, and A Reliability Framework and Asset Management SystemTM are the trademarks or registered trademarks of Reliabilityweb.com and its affiliates in the USA and in several other countries

There are three factors that must be addressed successfully in every MRO initiative - the technical aspect, communication, and change management. In my opinion, the weakest of these is communication. In most cases, those in technical roles do not speak with a business acumen that justifies the cost for the request being made. Since the initiative can only be as successful as the weakest point, communication to the decision makers must be improved and reflect business outcomes. There are two other items we need to dive into as well – properly defining what success should look like and the discipline to make the necessary changes for a successful outcome. All of these factors must be defined in terms that can be effectively communicated to MRO and organizational leadership in order to gain approval and funding. Examples include:

1. Upgraded/Improved asset performance

2. Improved software performance

3. Automation leading to less personnel

4. Increased production time and/or throughput

5. Decreased planned and unplanned downtime

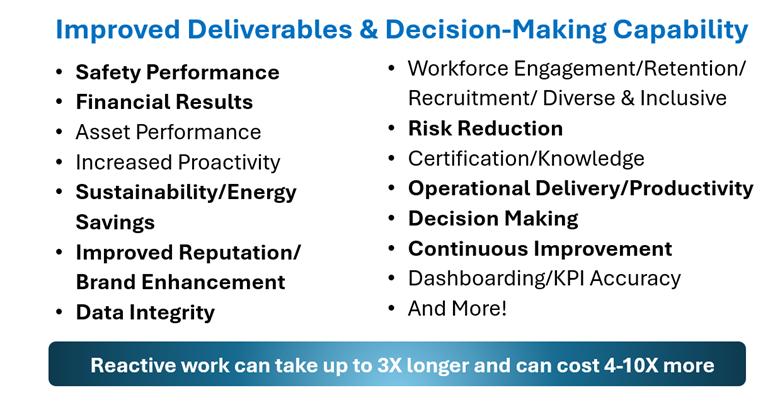

From a technical viewpoint, there is great value in these results; however, they are not the improvements that the C-Suite measures. To get the necessary funding and approval, correlation must be shown between MRO initiative deliverables and organizational business goals, requirements, key performance indicators (KPIs), etc. While Fig #2 is a comprehensive list of improvements, I have bolded several that will appeal to the C-Suite.

Fig#2 – Outcomes

* Information from SMRP Benchmarking

Once the applicable deliverables germane to the initiative are identified, how do we speak in “business” terms that align with our corporate needs? Money talks - how does this initiative increase revenue, reduce costs, improve efficiency, etc? What value does it bring – real and potential? A great example to use here is that in 2023 OSHA reported that for every $1 spent positively impacting safety, the company saves $3. Next, how does the initiative align to increase advantages and decrease the disadvantages of our business strategy? Lastly, how does it positively impact decision-making capabilities? Understanding that data is a key asset to decision-making, one must be able to communicate that impact and value. The last step is to take the information defined above and create an overall business case that captures the business and technical aspects of what this successful initiative will deliver; making sure to define thoroughly what factors will be necessary for success and how that success will be measured. Remember, an initiative does not have to be one hundred percent complete to create value. As an example, a baseball hitter must be successful three out of ten times to be considered a great hitter.

If all steps are followed to completion, is success guaranteed? The answer is no. All will have both successes and failures throughout their career. By covering all their bases, an organization is in a better position to achieve successful outcomes. The idea is to learn from both successes and failures, have more success, and increase the odds of being successful. There are things that can be done to create a “successful” mindset. Foremost, do not be afraid to fail. Anticipate and adapt while continuously trying to improve. Get better every day. Set an expectation for sustained success. Realize that the perfect program does not exist so look for opportunities to improve. Educate yourself, not just technically. As I was often reminded in my career, businesses are in the business to make money. Anything positively, ethically, and proactively one can do to help attain this goal will further the chance of achieving success.