Common Sense Reliability Expanded & Explained

Are you confident you're on the right path in your maintenance, reliability, and operations journey?

To create meaningful change, it is essential to understand both your current position and your desired destination. One of my favorite quotes sums this up: “You can’t go back and change the beginning, but you can start where you are and change the ending.” This sentiment is foundational to any conversation about improving a company’s performance or overall Maintenance, Reliability, and Operations (MRO) program.

This principle is also the cornerstone of change and Common Sense Reliability (CSR) is the mechanism to produce the change. Of course, additional tools - such as change management, effective communication, and knowledge sharing - are also needed. Russ Parrish Consulting (RPC) aides its clients in implementing all these elements to achieve a high degree of success.

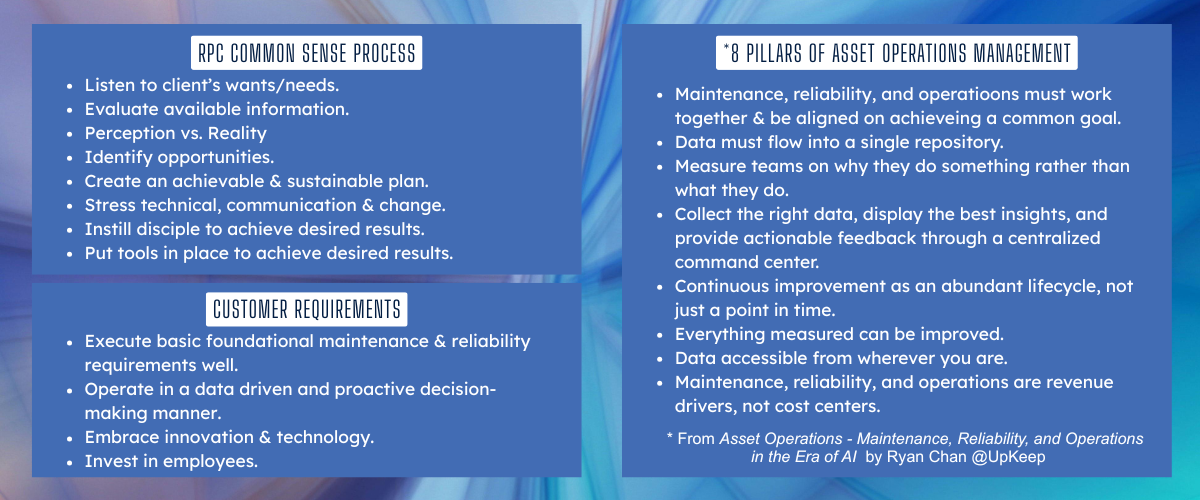

Common Sense Reliability - What is CSR? It is the model developed and used at RPC. It consists of three sections – RPC Common Sense Process; Customer Requirements; and 8 Pillars of Asset Management (From Asset Operations – Maintenance, Reliability, and Operations in the Era of AI by Ryan Chan @ UpKeep). RPC Common Sense Processes are the steps we follow in most customer projects. The steps are:

- Listen to the client's wants/needs – What are their problems, pain points, etc. Also, what are their needs and wants and why.

- Evaluate available information – CMMS, ERP, KPI, performance, downtime, etc. Preferably as much as is available, a minimum of 12 months' worth.

- Perception vs. Reality – Our observations of what the client thinks is happening versus what is actually occurring. This will be based on data and conversations.

- Identify opportunities – Actionable items that impact the wants and needs from above. Additionally, those items that could affect longer term strategies.

- Create an achievable & sustainable plan – Develop a plan that encompasses short, medium, and long term actionable deliverables to achieve defined opportunities.

- Stress technical, communication & change – Insure these three items are included in any project plan. Create milestones to track important goals.

- Instill discipline to achieve desired results – Establish accountability for action items.

- Put tools in place to sustain success – Have a strong governance policy and adhere to established standards.

Customer Requirements - A solid foundation for maintenance and reliability is built on four key areas:

- Execute basic foundational maintenance & reliability requirements well.

- Operate in a data driven and proactive decision-making manner.

- Embrace innovation and technology.

- Invest in employees.

In the September edition of the RPC Newsletter, we did a deep dive into the four areas of the Customer Requirements in the blog article,

Four Areas Needed to Build A Solid Maintenace and Reliability Program, refer back for details.

Figure #2

Eight Pillars of Asset Operations Management - The 8 Pillars of Asset Operations Management bridge foundational MRO practices with advanced best practice/world-class aspirations, including advanced technology areas like Internet of Thing (IoT), Artificial Intelligence (AI), Digital twins, and others:

- Maintenance, reliability, and operations must work together and be aligned on achieving a common goal.

- Data must flow into a single repository.

- Measure teams based on why they do something rather than what they do.

- Collect the right data, display the best insights, and provide actionable feedback through a centralized command center.

- Continuous improvement as an abundant lifecycle, not just a point in time.

- Everything measured can be improved.

- Data accessible from wherever you are.

- Maintenance, reliability, and operations are revenue drivers, not cost centers.

These three areas, when combiined, form a comprehensive approach (Figure #2). Not every item will apply to every organization; it is important to identify those that apply to your business model, current operational/maintenance state, and the urgency of your needs. By implementing these three areas businesses will have a strong MRO foundation; improved decision making, with better data quality; more skilled/satisfied employees; increased opportunity to successfully innovate and use advanced technologies; and find success in continuous improvement.

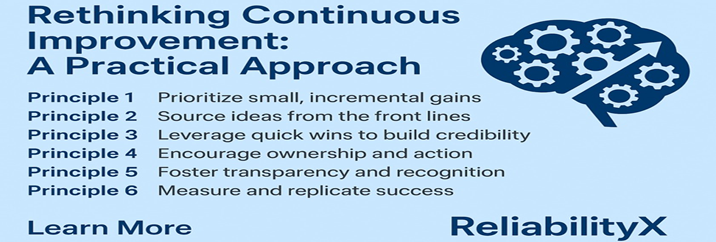

The ultimate goal is to note improvement each operation, shift, and day. Continuous improvement opportunities should be implemented and built upon. ReliabilityX has defined a great approach with six principles, stating: “Meaningful progress is attainable through a few core principles, paired with consistent execution. These principles are not revolutionary, but they are powerful when applied with intention. Here are several that can help drive real improvement within your organization:” This is a great take on this fundamental concept. Well done to the ReliabilityX team!

By combining continuous improvement with the other three aspects of CSR, businesses create a holistic, dynamic, and achievable MRO approach. If you have comments or questions, reach out to us at RPC. Have a blessed day.